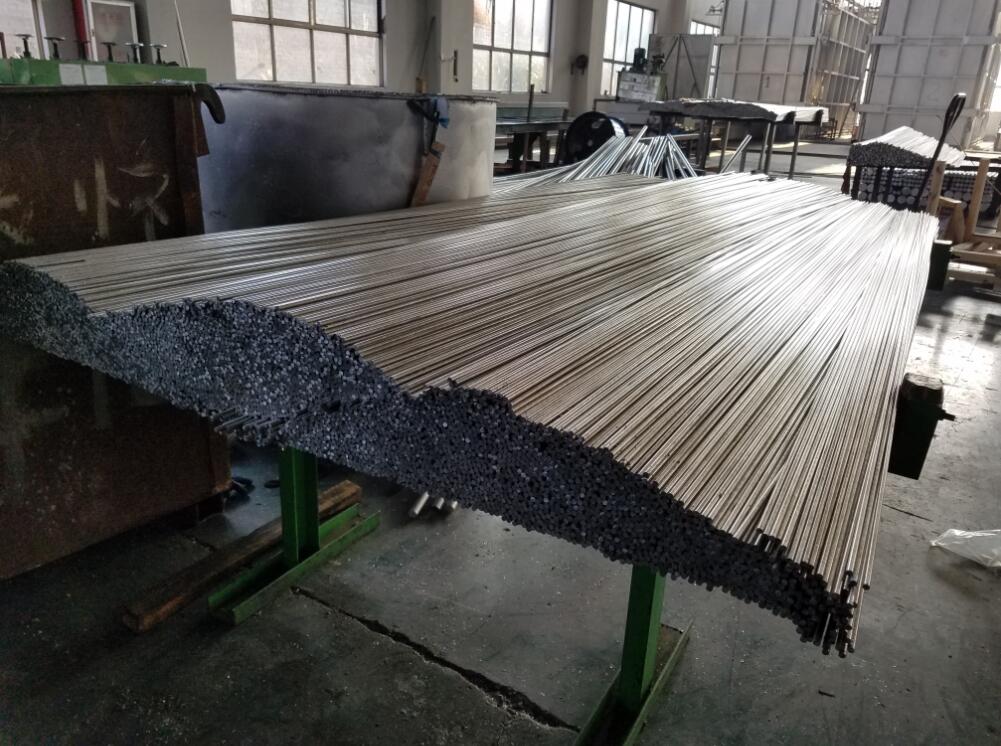

2618 aluminum round bar stock for sale chemical composition; (%)

Si; 0.10-0.25 Fe; 0.9-1.3 Cu; 1.9-2.7 Mn; / Mg; 1.3-1.8

Cr; /Ni; 0.9-1.2 Zn; 0.10 V; / Ti; 0.04-0.10 others; margin

2618 aluminum round bar stock for sale use;

2618 heat-resistant aluminum alloy is widely used in the manufacture of parts for aero engines and automobile industry;

(1) Compared with the T6 2618 alloy, the S′ phase in the 2618 alloy structure after thermomechanical treatment is significantly refined, but no dislocation entangled substructure or dislocation network is observed in the 2618 alloy structure after thermomechanical treatment. .

(2) The width of the precipitation-free zone (PFZ) in the structure of the 2618 alloy after thermomechanical treatment is narrowed, and the lean vacancy mechanism can better explain the change of the precipitation-free zone before and after thermomechanical treatment.

(3) A large number of dislocations produced by cold deformation will significantly increase the number of nucleation cores of S'phase in the 2618 alloy structure, and make the aging precipitated phase S'disperse uniformly in the alloy matrix structure.