Material state 0, T3, T4, T351, H112

Tensile strength σ b (MPa) 425, yield strength σ 0.2 (MPa) 275, elongation δ 5 (%) 12, hardness (HB) 120

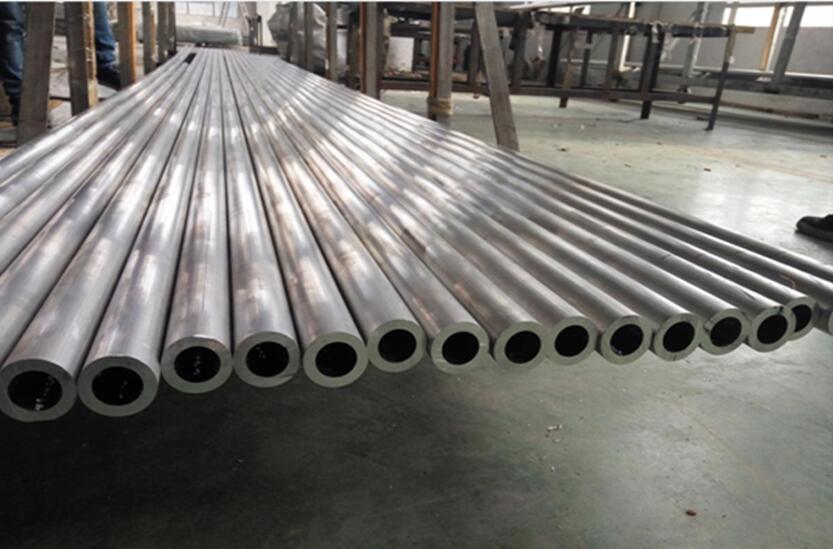

Extruded tube outer diameter φ 20mm' 300mm

Outer diameter of seamless pipe φ 20mm^ 600mm

Large-caliber aluminum tubes are customized according to customer requirements, and delivery is fast

Typical use molds, precision parts, etc.

2A12 aluminum alloy pipe tube is mainly used for alloy castings of structural parts such as aircraft wall panels, front beams, joints, pillars and landing gears, beauty equipment, and notebook shells. Used to make various high-load parts and components (but not stamping forgings) such as aircraft skeleton parts, skins, bulkheads, ribs, spars, rivets and other working parts below 150°C.