The main alloying elements of 6061 conductive seamless tubular bus tube pipe are magnesium and silicon, and form the Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is still a small amount of conductive material. Copper to offset the adverse effects of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function. The main alloying elements in6061 conductive seamless tubular bus tube pipe stock are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and good oxidation effect.

6061 conductive seamless tubular bus tube pipe is the main alloy of the 6-series alloy and is a high-quality aluminum alloy product that has undergone heat treatment and pre-stretching. 6061 has good processing performance, good corrosion resistance, high toughness, and no deformation after processing It has excellent characteristics such as easy color film and good oxidation effect.

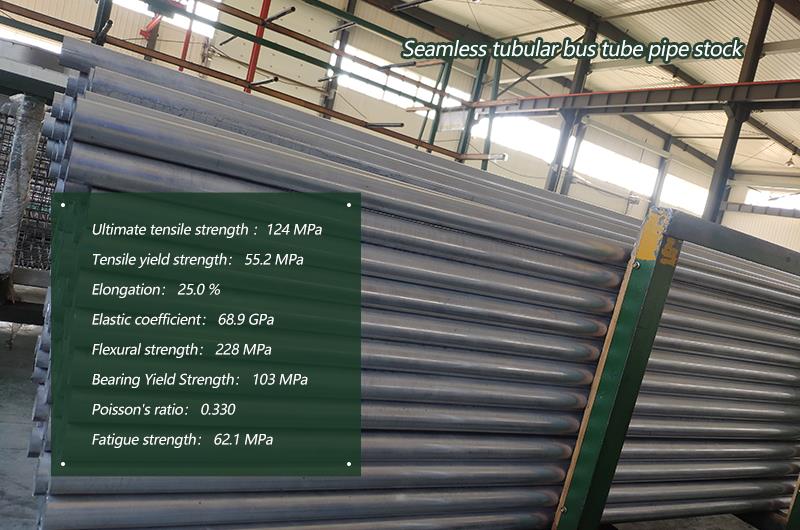

6061 conductive seamless tubular bus tube pipe stock

: Widely used in various industrial structural parts that require a certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, and road vehicles.

chemical composition(%):

Cu:0.15~0.4 Mn:0.15 Mg:0.8~1.2 Zn:0.25 Cr:0.04~0.35

Ti:0.15 Si: 0.4~0.8 Fe: 0.7 Al : margin

6061 conductive seamless tubular bus tube pipe stock properties:

The ultimate tensile strength of 6061 is 124 MPa

Tensile yield strength 55.2 MPa

Elongation 25.0 %

Elastic coefficient 68.9 GPa

Flexural strength 228 MPa

Bearing Yield Strength 103 MPa

Poisson's ratio 0.330

Fatigue strength 62.1 MPa