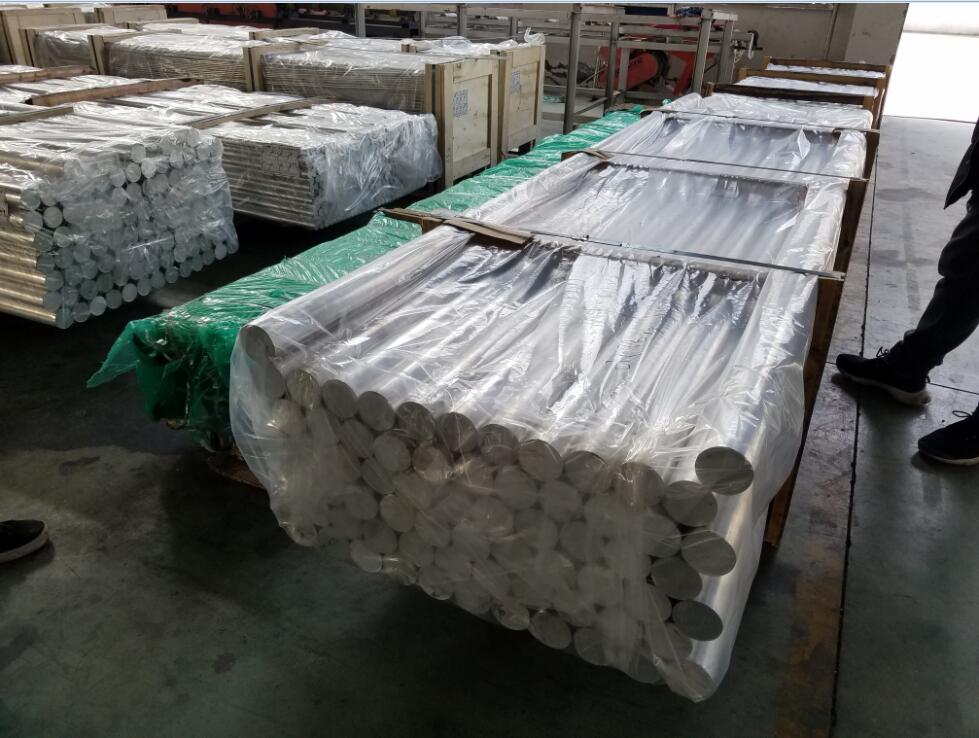

Grade: 6066

6066 aluminum rod characteristics and applications:

6066 aluminum alloy has poor corrosion resistance and good welding performance. 6066 aluminum alloy is suitable for forgings and extrusions for welded components.

6066 aluminum rod standard control:

American Aluminum Association (AA) 6066, UNS A96066

6066 chemical composition:

Aluminum Al (minimum): balance silicon Si: 0.9~1.8 iron Fe: ≤0.50

Copper Cu: 0.7~1.2 Manganese Mn: 0.6~1.1 Magnesium Mg: 0.8~1.4

Chromium Cr: ≤ 0.40 Zinc Zn: ≤ 0.25 Ti Ti: ≤ 0.20

6066 aluminum rod features:

1. Good formability and weldability.

2. High strength.

3. Good usability and excellent interface characteristics.

4. Easy to process and easy to coat.

5. Good corrosion resistance and oxidation resistance.

6066 aluminum rod main use:

Aerospace fixtures, trucks, tower buildings, boats, pipelines and other areas of construction that require strength, weldability and corrosion resistance. Such as: aircraft parts, camera lenses, couplers, marine accessories and hardware, electronic accessories and connectors, decorative or various hardware, hinged heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts.