6061 brushed aluminum plate mainly contains two elements: magnesium and silicon. Brush polish Aluminum plate A6061 T6 with PVC cover in stock is a cold-treated aluminum forging product, suitable for applications with high requirements for corrosion resistance and oxidation. Good workability, excellent interface characteristics, easy coating, and good processability. It can be used on low-pressure w...

3003 extruded aluminum round bar stock

3003 series aluminum is a common product in the aluminum-manganese alloy series. Due to the manganese alloy element, this product has anti-rust properties, and is also called anti-rust aluminum plate. The strength is about 10% higher than 1100, and the formability, weldability, and corrosion resistance are all good. Used for processing parts that require good formability, high corrosion resistance ...

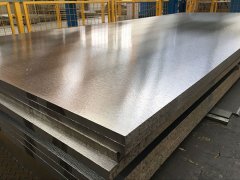

aluminium 5754 H22 grade material stock

The 5754 aluminum plate belongs to the Almg3 series, and the magnesium alloy content is higher than that of the 5052 aluminum plate. aluminium 5754 H22 grade material stock belongs to the medium-strength aluminum alloy plate, the magnesium alloy content is between 2.6-3.6, and it has good rust and corrosion resistance, no color difference on the anodized surface, excellent processing performance, e...

5005 aluminium alloy coil sheet supplier

5005 aluminium alloy coil sheet are often used as conductors, cooking utensils, instrument panels, shells and architectural decorations, building materials for interior and exterior decoration, and vehicle interior decoration. Chemical composition of 5005 aluminum plate. Edit. Aluminum Al: remaining silicon Si: 0.3 Copper Cu: 0.2 Magnesium Mg Inventory: real-time changes, please consult customer...

4004 3003 4004 aluminum brazing clad sheet roll

Application scope: oxygen production equipment and radiator for automobile industry, etc. Alloy state: O, H14, H18 Can produce alloy thickness: 1.0-3.0mm Processing technology: hot rolling As a kind of brazing filler metal, aluminum-based alloy has a melting point above 450C, and the brazing temperature is usually selected to be 25C-60C higher than the liquidus temperature of the solder to ensure t...